Facilities management has never stood still. From paper-based asset registers to CAFM systems, and reactive maintenance to predictive analytics, the industry continues to evolve.

Several trends are converging to progress this momentum. Sensors are cheaper and easier to deploy than ever, IoT platforms are mature and scalable, and BIM adoption is increasing across the FM sector. As we explored in our last blog Why starting your BIM journey is getting easier, the barriers to entry are falling.

The next logical step in this digital journey is the digital twin. But is FM ready for it?

What is a digital twin in an FM context?

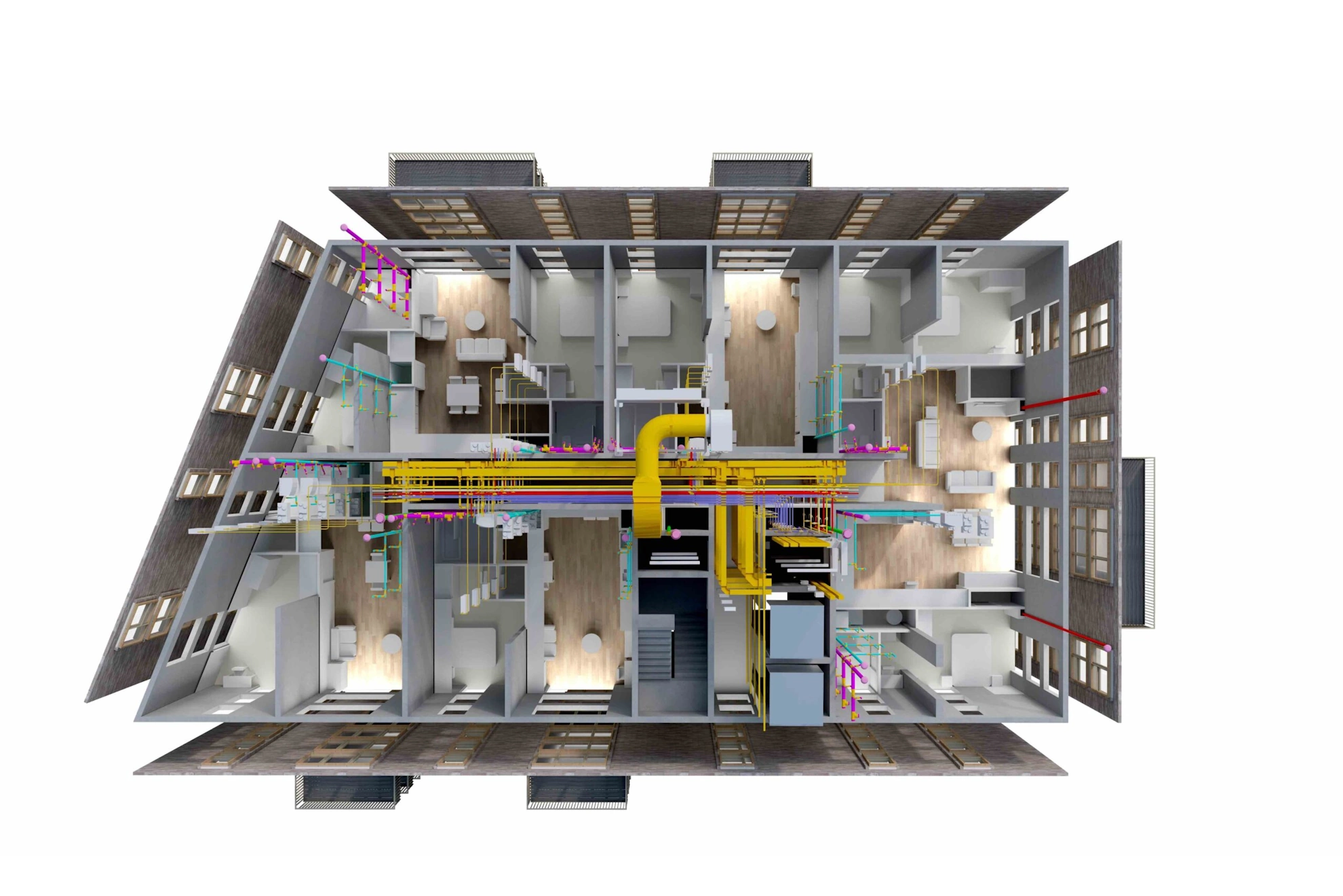

A digital twin is more than a 3D model. It’s a dynamic, accurate virtual representation of a building or estate that reflects both its physical structure and its real-time operational performance.

It combines:

- Physical layer (the ‘as built’ data, from a BIM model)

- Building system layer (a BMS or IoT sensors to deliver real-time data from systems and components)

- People layer (delivering behavioural data)

- Enterprise layer (CAFM software relating to processes across facilities and property management)

The result is a continuously updated operational model that can be monitored, analysed, simulated and optimised.

Digital twins are being used in major infrastructure projects worldwide, from Olympic Games venues to transport networks and city-scale digital environments. For events such as the Olympics, digital twins have supported complex coordination, capacity modelling, energy optimisation and risk management. They enable planners to simulate crowd flows, test operational scenarios and reduce risk long before doors open to the public.

While those examples operate at city or infrastructure scale, the same principles apply to hospitals, universities, transport hubs and commercial estates during the operational phase. The technology is proven, and increasingly accessible.

Why is a digital twin valuable for facilities management?

A digital twin gives facilities teams better visibility and control across the building lifecycle. By connecting geometry, live data and operational history, FMs gain a single, contextualised source of truth. Instead of viewing asset data, floorplans and sensor readings in isolation, they can see how everything interacts in real time.

The benefits include:

- Predictive maintenance

Digital twins help shift maintenance strategies from reactive or preventative to predictive. By combining sensor data with performance history, teams can identify early signs of degradation, such as gradual efficiency decline in HVAC systems, before thresholds are breached. This reduces emergency call-outs, limits downtime and optimises servicing schedules. - Lifecycle optimisation

Bringing asset data, maintenance records and spatial context together makes it easier to identify performance patterns, cost drivers and risk areas. This supports better capital planning, longer asset life and stronger compliance performance, which are particularly important in PPP and long-term performance-based contracts. - Scenario modelling (“what if?” analysis)

Digital twins allow FMs to simulate change safely. What happens if occupancy increases? How will ventilation cope? What is the impact of extended operating hours on asset life? Testing scenarios virtually reduces operational risk and informs smarter decisions. - Space utilisation and user experience

By analysing occupancy and movement patterns, FMs can optimise layouts, consolidate underused areas and improve workplace experience. In sectors such as healthcare, insights from digital twins can influence future design decisions to improve patient care and speed of services. - Energy and sustainability optimisation

While sensor and BMS integration can turn off heating and lighting to vacant rooms, a digital twin goes further by adding context. Linking energy data to building layout, asset performance and usage patterns enables deeper analysis and more strategic decision-making. This supports carbon reduction, ESG reporting and more efficient portfolio-wide planning.

Beyond these five core areas, digital twins also enhance compliance tracking, improve remote diagnostics, support safety planning, strengthen stakeholder reporting, and more.

How to transition to a twin

Many organisations already have the foundations of CAFM and BMS software in place, so taking the next step need not feel overwhelming.

The most effective approach is to start small. We recommend to our clients that a pilot based on one building or critical area can demonstrate value quickly, before scaling across a portfolio. As discussed in the last blog, a BIM model using our Plan to BIM method could be created in days instead of weeks, or weeks instead of months, depending on the building / site size and complexity.

Digital twins are no longer experimental technology reserved for flagship infrastructure projects. They are a practical, scalable step forward for facilities management. The future is connected, data-driven and predictive.

Keep up to date on the latest industry and technology developments. Sign up to receive SWG’s blog delivered straight to your inbox: