There’s no secret to the benefits of planned preventative maintenance (PPM) compared to reactive maintenance. Timely servicing of assets reduces unexpected breakdown and inconvenience, minimises costs compared to a repair, and extends equipment life. According to the FM Tech Survey 2020, around 85% of respondents with CAFM software are using it to help manage planned maintenance. Creating schedules for each asset is a daunting task on a spreadsheet, but CAFM makes the process simple – and even more so when integrated with industry standard regimes like SFG20.

What is SFG20?

SFG20 was created in 1990 by the Building Engineering Services Association (BESA) and is recognised as the UK industry standard for building maintenance specifications. The database contains over 1200 maintenance schedules for more than 70 equipment types, which are kept updated by BESA. This removes the requirements of consulting the manufacturer guidelines for each asset, saving FMs time and hassle whilst making it easier for an organisation to remain compliant.

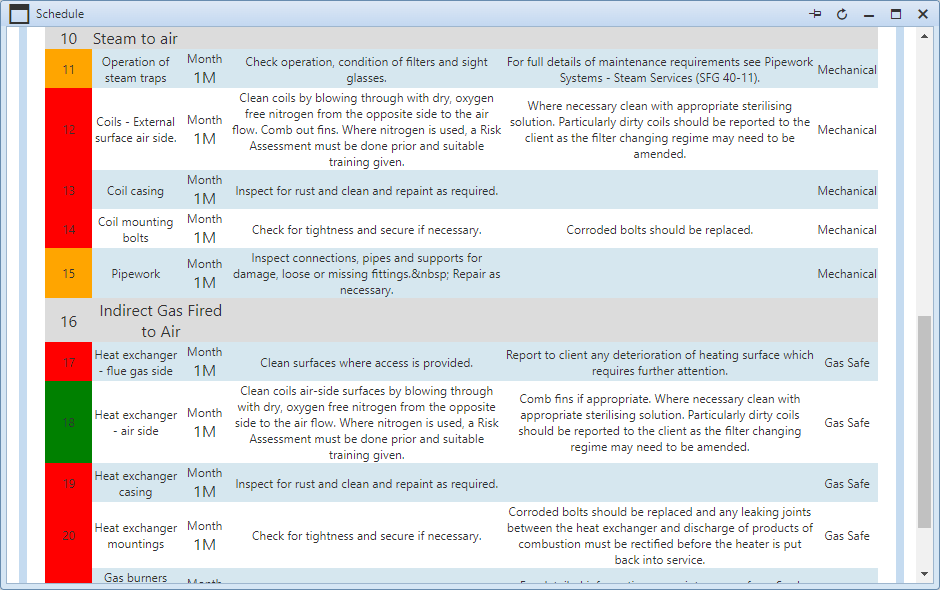

What information is included in SFG20 maintenance schedules?

Schedules include step-by-step tasks of what is required to maintain each asset, the frequency with which each task should be performed to avoid under- or over-maintaining, and what skills are required from the engineer (mechanical, gas safe, electrical etc).

A colour-coding system is used to help prioritise tasks in order to optimise maintenance. SFG20 task maintenance schedules display the recommended rating based on legislation, regulations and industry best practice.

- Red – statutory / legal (to ensure legal compliance)

- Pink – mandatory / business critical (to ensure sector / organisation compliance)

- Amber – optimal (function critical and industry best practice)

- Green – discretionary (non-critical maintenance).

How is SFG20 used in practice?

As SFG20 is web-based, it can be integrated with the more progressive CAFM systems, like Service Works Global’s QFM software. QFM can also integrate with other external entities to accept feeds for similar types of maintenance data used for different purposes or in other geographical regions.

Rather than performing a blanket import, FMs can choose which schedule templates are actively linked to the QFM maintenance schedule; and configure them as required. Some tasks may not be applicable to a site and failure to remove them can cause confusion in a contract, so it’s easy to review and disable tasks on the CAFM side. As and when schedules are updated by BESA, changes are automatically pulled through to QFM so FMs can be sure they are always following the best guidance and remain compliant with legislation.

Can SFG20 be used with BIM?

The Hackitt Review following the Grenfell Tower disaster has placed emphasis on digitising processes and establishing best practice across the building lifecycle. SFG20 schedules within CAFM software can be used as part of the Golden Thread to show maintenance has been planned to meet industry standards; time and date stamped upon completion for auditability. Organisations using BIM will be pleased to know that BESA is has formed a partnership with NBS, who developed the Uniclass 2015 construction classification structure; in order to drive digital adoption across the building lifecycle.

Uniclass 2015 uses tables to classify all items from a whole facility down to a door hinge, standardising how project information is classified and is a requirement of BIM (set out by ISO 19650). Maintenance schedules are generally developed for assets as described in the Uniclass specifications, so the bodies are working together to map the two systems and ensure Uniclass and SFG20 align.

Sarah Delany, Head of Classification at NBS, said: “The construction industry is increasingly digital and by mapping between the two systems clients can more easily take a whole-life approach to their building projects. Thus bringing the golden thread one stitch closer.”

For more information on planned preventative maintenance, asset management or QFM integration with SFG20, contact us here.

Keep up to date on the latest industry and technology developments: sign up to receive SWG’s blog delivered straight to your inbox: